Angle and torque wrench MANOSKOP®

Angle and torque wrench MANOSKOP®

714

- An angle and torque wrench for bolted joints in accordance with the torque, angle of rotation, torque with "angle of rotation" monitoring variable and angle of rotation with "torque" monitoring variable tightening method.

- Electromechanically displaying (with electronic measurement) and triggering (with the familiar mechanical “click”).

- Visual evaluation of the bolted joint.

- Simple documentation of the recorded measurements on the PC via the USB interface and via an optional Bluetooth Low Energy module.

- Thanks to the combination of the patented electromechanical triggering and the display and acoustic feedback, the wrench provides signalling with maximum optimisation.

Produkt-Varianten

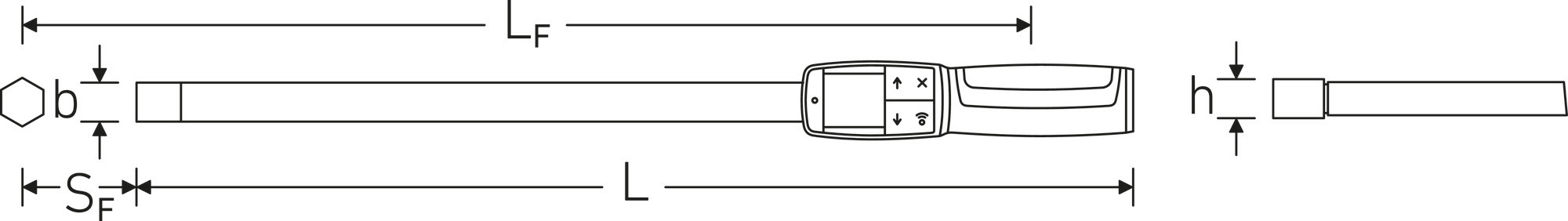

| Product no. | Size | Model | Measuring range N·m | Measuring range ft-lb | Measuring range in-lb | Length mm (L) | Width mm (b) | Height mm (h) | Battery type | Tool holder size [internal square] | LF | SF | Weight (g) | Weight with box | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 96500100 | 100 | 714 | 100-1000 N·m | 74-750 ft·lb | 900-9000 in·lb | 1343 mm | 30,6 mm | 25,6 mm | Micro (AAA) 1,5V | 22 x 28 mm | 1343 mm | 55 mm | 4990 g | 10500 g | Jetzt entdecken |

| 96500901 | 1 | 714 | 1-10 N·m | 0,7-7,5 ft·lb | 9-90 in·lb | 226 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 9 x 12 mm | 188 mm | 17,5 mm | 370 g | 795 g | |

| 96500902 | 2 | 714 | 2-20 N·m | 1,5-15 ft·lb | 18-180 in·lb | 226 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 9 x 12 mm | 188 mm | 17,5 mm | 380 g | 805 g | Jetzt entdecken |

| 96500904 | 4 | 714 | 4-40 N·m | 3-30 ft·lb | 36-360 in·lb | 252 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 9 x 12 mm | 214 mm | 17,5 mm | 420 g | 845 g | Jetzt entdecken |

| 96500906 | 6 | 714 | 6-60 N·m | 4,5-45 ft·lb | 54-540 in·lb | 393 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 9 x 12 mm | 355 mm | 17,5 mm | 810 g | 1235 g | Jetzt entdecken |

| 96500910 | 10 | 714 | 10-100 N·m | 7,4-75 ft·lb | 90-900 in·lb | 466 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 9 x 12 mm | 428 mm | 17,5 mm | 1085 g | 1655 g | Jetzt entdecken |

| 96500920 | 20 | 714 | 20-200 N·m | 15-150 ft·lb | 180-1800 in·lb | 547 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 14 x 18 mm | 516 mm | 25 mm | 1361 g | 1896 g | Jetzt entdecken |

| 96500940 | 40 | 714 | 40-400 N·m | 30-300 ft·lb | 360-3600 in·lb | 687 mm | 28 mm | 23 mm | Micro (AAA) 1,5V | 14 x 18 mm | 656 mm | 25 mm | 1765 g | 5155 g | Jetzt entdecken |

| 96500965 | 65 | 714 | 65-650 N·m | 48-480 ft·lb | 580-5800 in·lb | 890 mm | 30,6 mm | 25,6 mm | Micro (AAA) 1,5V | 22 x 28 mm | 890 mm | 55 mm | 3222 g | 7000 g | Jetzt entdecken |

| 96500980 | 80 | 714 | 80-800 N·m | 60-600 ft·lb | 720-7200 in·lb | 1158 mm | 30,6 mm | 25,6 mm | Micro (AAA) 1,5V | 22 x 28 mm | 1158 mm | 55 mm | 4572 g | 10400 g | Jetzt entdecken |

Technologien und Leistungsmerkmale

2-component handle

QuickRelease

DIN EN ISO 6789-2

Eigenschaften

- electromechanical triggering

- acoustic and visual trigger signal

- 4 measuring modes (torque, angle of rotation, torque with 'angle of rotation' monitoring variable, angle of rotation with 'torque' monitoring variable)

- high-resolution colour OLED display and side signal lights

- visual evaluation of the bolted joint: yellow light (pre-warning threshold reached), green light (within tolerance range), red light (measurement outside tolerance range)

- freely configurable menu structure

- battery compartment/battery pack with bayonet connection

- optional: Li-ion battery no. 7195-2 and charger no. 7160

- 3 function modes: triggering (patented electromechanical triggering), peak-hold (indicating mode with peak value display) and track (indicating mode with actual value display)

- micro USB interface for data communication

- optional Bluetooth low energy-module (5.2)

- QuickRelease safety lock - switching system for insert tools

- data storage for up to 2,500 processes, including date and time stamp

- up to 200 joints in a maximum of 25 guided sequences can be programmed

- different tolerance limits adjustable depending on the type of bolted joint

- fast and precise setting via the keypad

- no unintentional adjustments thanks to password-protected keypad lock

- acoustic and visual signal warns of torque wrench overload and forced triggering in clockwise tightening mode

- automatic indication of the next calibration date, user-configurable according to elapsed time and/or number of operations

- fully automatic calibration and adjustment with the perfectControl® calibration and adjustment device No. 7794-2 (torque) or 7794-3 (torque and angle of rotation) for reducing error influencing factors

- units of measurement: N·m, ft·lb, in·lb

- automatic extension length correction: when an insert tool with a non-standard extension length is used, input the extension length to ensure that the required target value is achieved

- ready for operation again immediately after release

- clockwise and anticlockwise tightening - the insert tool must be flipped over for anticlockwise torque in 'triggering' function mode

- torque and angle of rotation displays simultaneously

- measurement regardless of the force application point (for sizes 1, 2, and 4)

- safe handling due to the ergonomically shaped 2-component handle (resistant to the most common oils, greases, fuels, brake fluids and Skydrol)

- 3 certificates included (torque indicating/triggering in accordance with DIN EN ISO 6789-2:2017, angle of rotation based on VDI/VDE 2648-2)

- in sturdy plastic box (sizes 40-100 in steel box)

- registered design, patented

- supplied with SensoMaster 4 software, USB cable, 4 batteries AAA/LR03, 1.5 V

- angle of rotation display resolution 0.1°

- angle of rotation accuracy ± 1°, ± 1 digit to 100°, >100° at least 1%, ± 1 digit

- torque display resolution ≤ 60 N·m: 0.01 N·m; > 60 N·m: 0.1 N·m; > 400 N·m: 1 N·m

- torque accuracy ± 2%, ± 1 digit

Produkt-Highlights

Angle of rotation and torque measurement

Our torque and angle wrenches make it possible to tighten bolted joints in accordance with the torque, angle of rotation, torque with 'angle of rotation' monitoring variable and angle of rotation with 'torque' monitoring variable tightening method. Thanks to this functional diversity, the wrench is suitable for the most popular tightening methods.

Electromechanical clicking type.

The MANOSKOP® with patented electromechanical release measures the applied torque electronically. A visual evaluation of the bolted connection is provided by a display and signal lights on the side. Unlike a purely electronic torque wrench, the cycle and haptic user feedback are also mechanical. A clearly perceptible cycle and an equally audible click indicate that the target value has been reached.

Comprehensive documentation.

Our electromechanical torque wrenches can be documented. They can be easily configured and programmed using the SensoMaster software. This means that all data can be read out, stored and subjected to further processing on the PC for better monitoring and optimization of the work processes. The digital measurement also allows the actual torque which has been applied (actual value) to be specified after triggering, as well as the target value.

Also suitable for difficult application areas.

STAHLWILLE electromechanical torque wrenches are ideal for application areas in which electronic torque wrenches are pushed to their signalling limits - such as when working overhead or if the display cannot be read off. Even in noisy, busy and very bright environments which can make it difficult to perceive vibrations or visual and acoustic signals, electromechanical torque wrenches use patented haptic feedback to indicate that the target value has been reached.

More reliability.

Our electromechanical torque wrenches minimise operating errors. Screw joints and sequence plans, for example, can be parameterized and saved. The torque wrench then automatically sets the clicking type torque for the selected bolted joint. The clicking type torque is also specified digitally so that parallax effects (errors caused by to an incorrect reading angle), which are possible when using a mechanical scale are eliminated.

Perfect entry level solution.

Electromechanical STAHLWILLE torque wrenches make it easier to switch from purely mechanical to documenting torque wrenches. Users who previously only worked with mechanical wrenches become accustomed to them more quickly because our electromechanical torque wrenches provide maximum optimized signalling with haptic, acoustic and visual feedback. This simplifies the switch to digital technology.