Checked. Documented. Accredited.

In-house calibration – your benefits.

Process reliability and flexibility

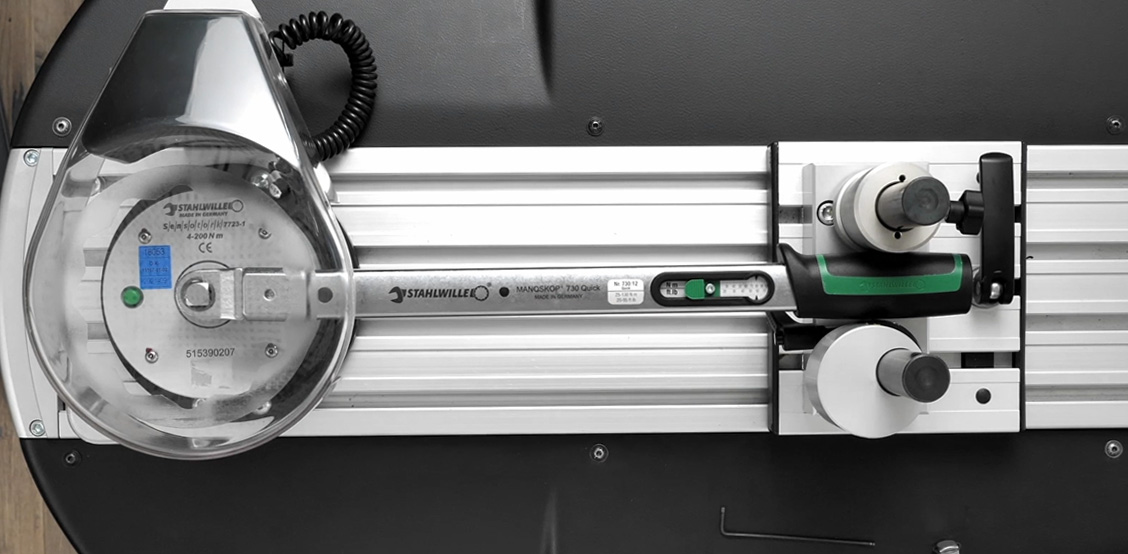

- With a calibration unit from STAHLWILLE, you benefit from maximum process reliability, reliable quality control and the highest efficiency.

- You can calibrate frequently and efficiently - at no extra cost.

- Or you can calibrate at times when the tool is not needed. It is completely flexible, depending on the production capacity.

Time-saving

- Your own calibration unit will relieve your team and reduce your tool downtime!

- You save the internal administrative burden of sending a tool to an external calibration laboratory - and thus valuable work time.

- You also reduce transport times because your tool is no longer unnecessarily in transit and is therefore available for longer.

Fast amortization

- External calibration of torque wrenches is becoming more and more expensive.

- It can also unnecessarily tie up capital because you may need to have spares for the time you are without your tools.

- That's why investing in your own calibration units pays off faster than you think - especially if you use torque tools that need to be calibrated on a daily basis!

Find individual savings potential now!

Increasing requirements.

A calibration unit from STAHLWILLE makes an important contribution to making your business more efficient, more profitable and more safe. Today more than ever, because the demands on standard-compliant tightening and bolting are high.

Our service: your advantage.

Our application specialists will help you make your investment decision: Whether it's testing and calibration standards or our products. On site, in online meetings, via a webinar or with us in Wuppertal, we will work with you and your STAHLWILLE dealer to find the optimal calibration solution.

To help users work safely and efficiently, our state-of-the-art information center in the historic STAHLWILLE office in Wuppertal-Cronenberg offers on-the-job training for individuals and teams, as well as user training for our calibration equipment and software.

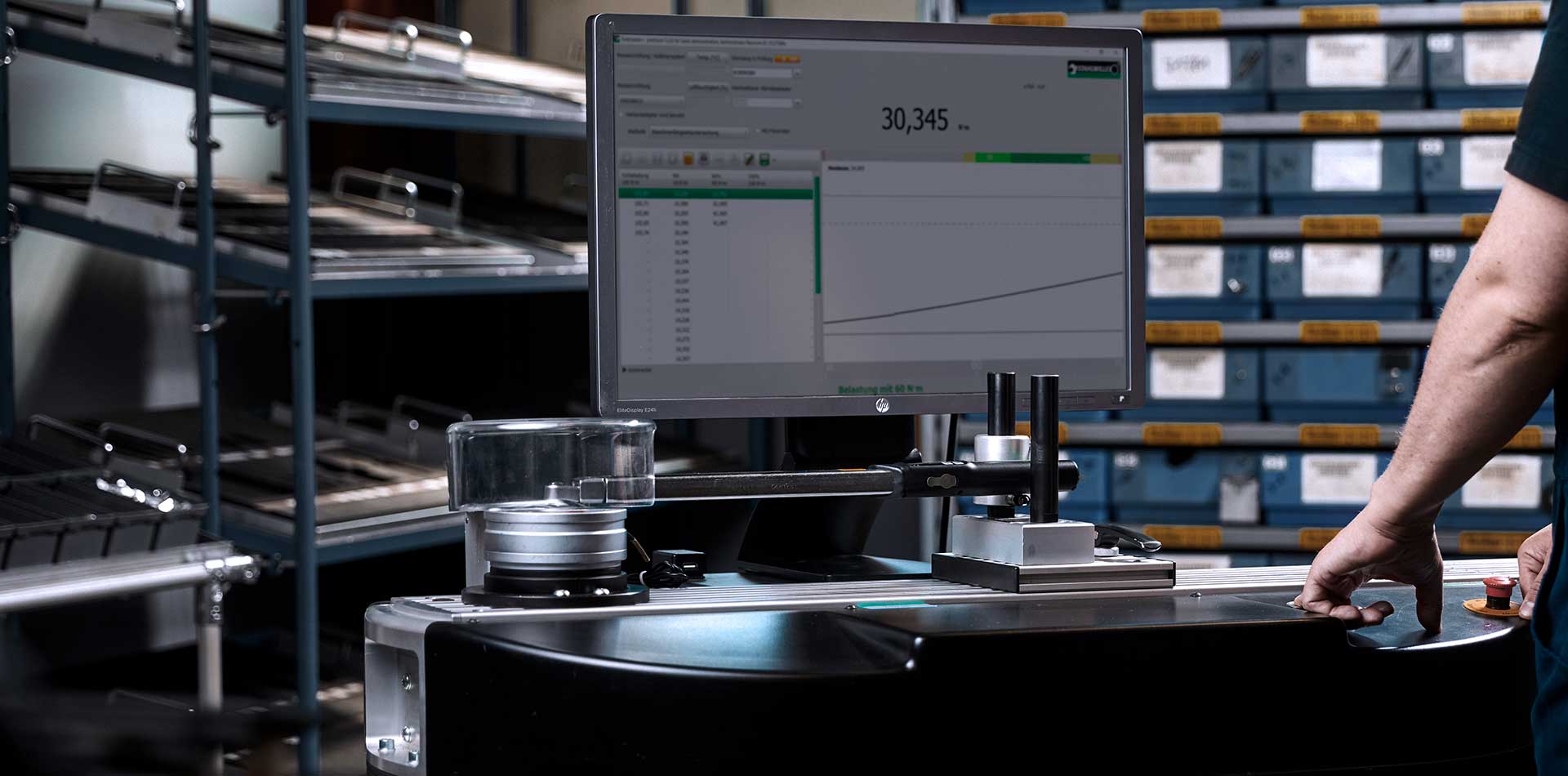

Take advantage of our regular webinars. This is where you can expand your expertise online and have direct contact with our experts. For example, in the webinar "Increasing process reliability and quality with testing and calibration technology" or in the webinar on our testing and calibration software TorkMaster.

Our support team is at your side from the very first moment: By video call or on-site, they will help with commissioning and will answer your questions. In addition, the support team will always be there to help you with product, software or application issues, as well as troubleshooting or process optimization.

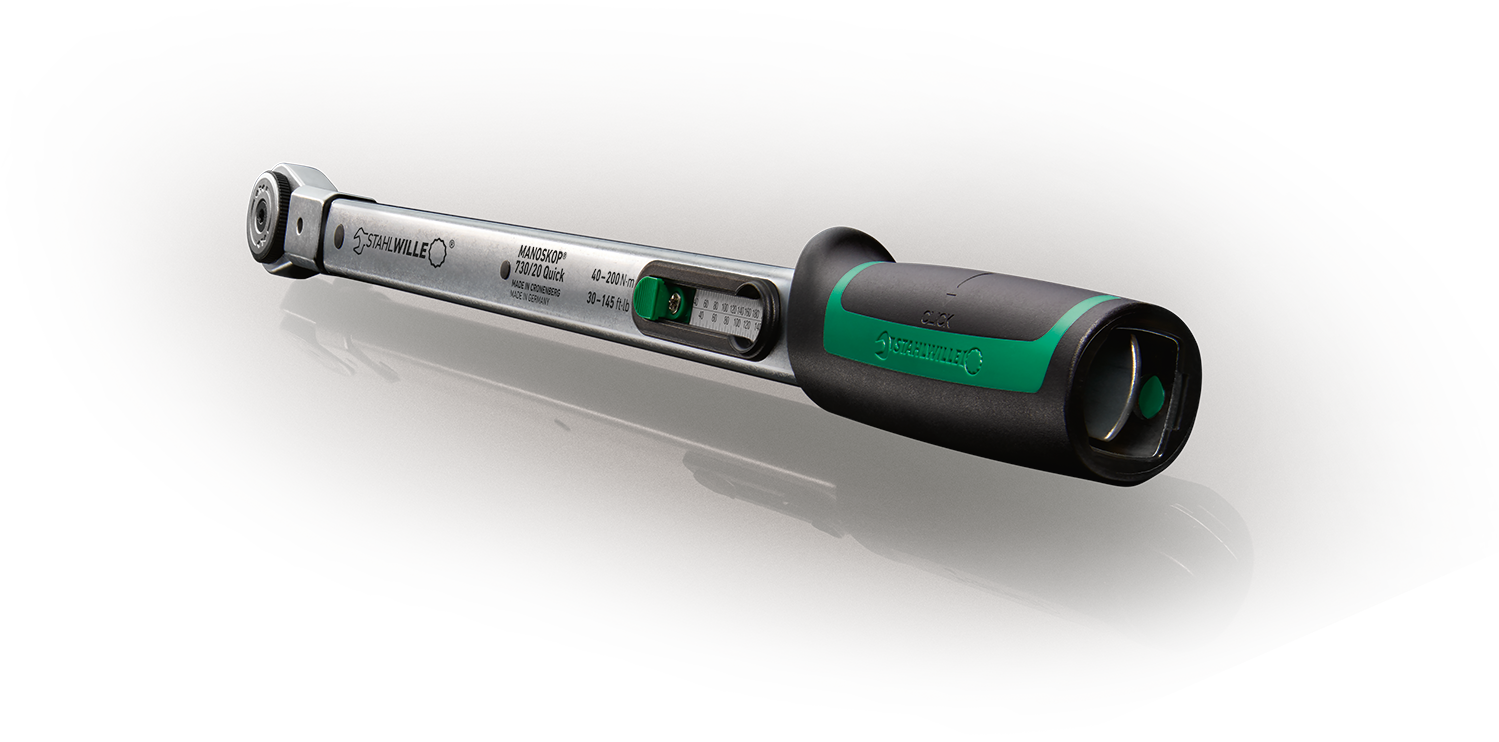

With TorkMaster, STAHLWILLE offers you a free, powerful, user-friendly and almost self-explanatory software solution for calibrating your hand torque tools. From the graphical presentation of the test history, to the documentation of all measurement data and the integrated tool history, to the issuing of official test and calibration certificates and integration into your CAQ system: TorkMaster makes the calibration process safe, time-efficient and painless. In interaction with the perfectControl® calibration unit, it is even possible to operate semi automatically.

Download the calibration brochure now!

Download our brochure on calibration technology. With it you will learn everything about advantages, connection options, models, software and what we do for you before and after purchase.

Contact