Electronic angle and torque wrench SENSOTORK®

Electronic angle and torque wrench SENSOTORK®

713R

Artikel-Nr. 96501620|EAN 4018754156511

Produkt-Varianten

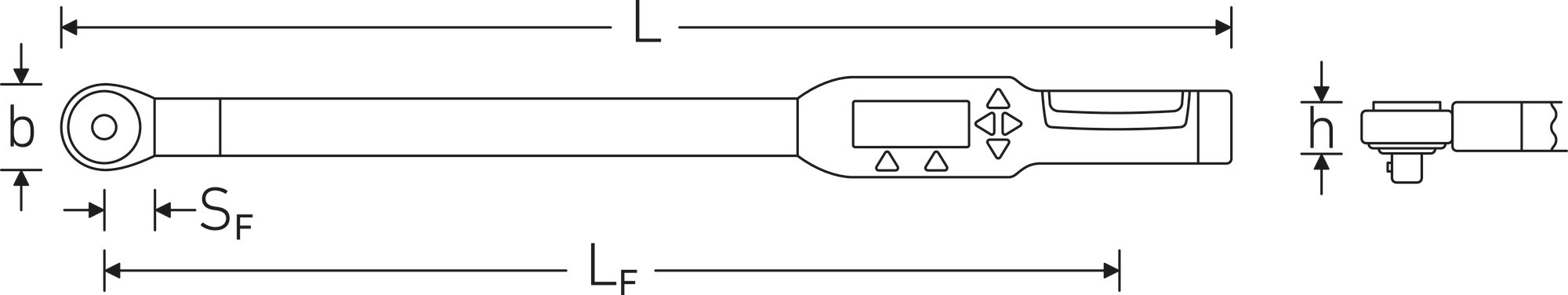

| Product no. | Size | Model | Measuring range N·m | Measuring range ft-lb | External square drive (inch) | Length mm (L) | Width mm (b) | Height mm (h) | Number of teeth | Battery type | Tool holder size [internal square] | LF | SF | Weight (g) | Weight with box | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 96501606 | 6 | 713R | 3-60 N·m | 2,5-44 ft·lb | 3/8 | 378 mm | 33 mm | 24 mm | 60 | Mignon (AA) 1,5V | 9 x 12 mm | 299 mm | 17,5 mm | 856 g | 1500 g | Jetzt entdecken |

| 96501620 | 20 | 713R | 10-200 N·m | 7-148 ft·lb | 1/2 | 608 mm | 43 mm | 26 mm | 60 | Mignon (AA) 1,5V | 14 x 18 mm | 524 mm | 25 mm | 1552 g | 2430 g | |

| 96501640 | 40 | 713R | 20-400 N·m | 15-296 ft·lb | 3/4 | 838 mm | 50 mm | 31,5 mm | 60 | Mignon (AA) 1,5V | 14 x 18 mm | 750 mm | 25 mm | 2332 g | 5555 g | Jetzt entdecken |

Technologien und Leistungsmerkmale

DIN EN ISO 6789-2

Our torque wrenches and torque screwdrivers are professionally calibrated in accordance with DIN EN ISO 6789-2 and delivered with a corresponding calibration certificate. We also calibrate the torque and angle wrenches in accordance with VDI 2648-2. This ensures the accuracy and traceability of our tools.

QuickRelease

The QuickRelease safety lock prevents unintentional loss of insert tools. These click securely into place and are only released again at the push of a button for a quick tool change.

Eigenschaften

- simple and flexible operation thanks to menu guidance on the large display

- particularly broad measurement range (5-100 % of the nominal value)

- includes reversible ratchet No. 735

- with QuickRelease safety lock

- for clockwise and counter-clockwise tightening

- measurement independent of the point of force application

- convenient angle of rotation measurement with an extremely wide angle of rotation range

- units of measurement: N·m, ft·lb, in·lb

- prewarning threshold for visual, tactile and acoustic signals can be set

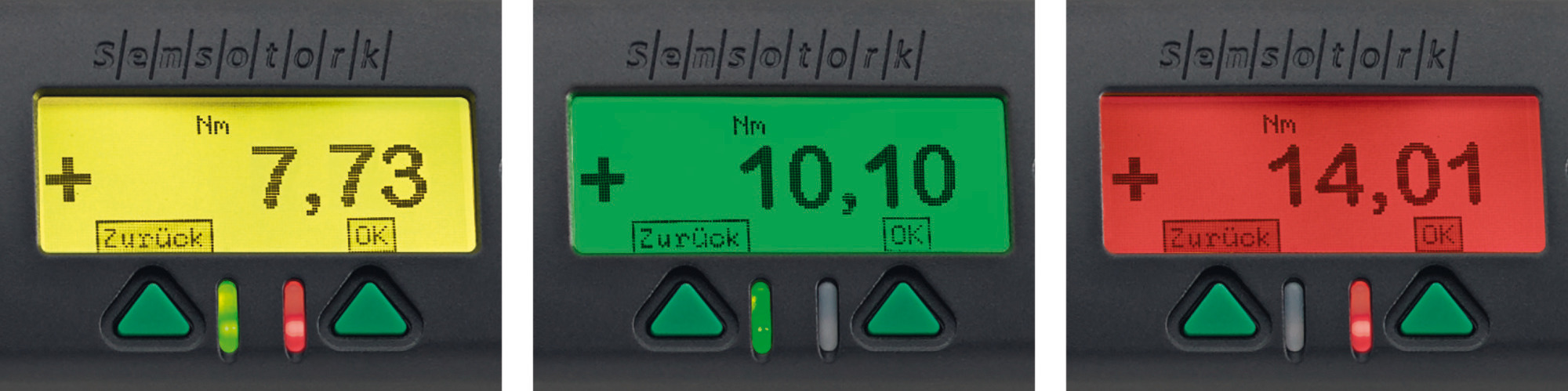

- multicoloured backlit LED display gives visual cue about the status of the process (traffic light principle)

- extension length compensation function: automatic compensation of the tightening torque when a deviating extension length is entered

- easy to maintain thanks to simple adjustment and automatic notification of the next calibration date

- multiple bolted joints can be combined into a menu-guided sequence

- tightening operations are saved with a date and time stamp

- individual identification designation possible

- password protection against unintentional adjustment and unauthorised access

- compliant with DKD-R 3-7, class 2

- with 2 calibration certificates (torque in accordance with DIN EN ISO 6789-2:2017/angle of rotation based on VDI/VDE 2648-2)

- in sturdy plastic box (size 40 in sturdy steel box)

- supplied with 2 x 1.5 V AA batteries. NiMH batteries AA/LR6, 1.2 V can also be used.

- fully automatic calibration (torque) with the perfectControl® calibration system No. 7794-2

- readjustment does not require disassembly

- torque and angle of rotation are visible at the same time

- angle of rotation accuracy ± 1°, ± 1 digit to 100°, >100° at least 1%, ± 1 digit

- torque accuracy ± 1 %, ± 1 digit

Produkt-Highlights

Precision measurement.

Accuracy counts - uncertainty is reduced to a minimum to guarantee accurate readings.

Multisensory.

The torque achieved is indicated by visual, audible and tactile signals - with a multicoloured backlit LCD display, acoustic signal and vibration.

In unserem Kundenportal bieten wir weitere Informationen und Downloads.

Zubehör-Artikel.

Service

2025© All Rights Reserved