Separation assemblies

Separation assemblies

11500

- For use with puller 11501.

- For quick separation and extraction of tight fitting parts such as gears, ball bearings and belt pulleys.

- Sharp jaws make reliable detachment possible in areas where there is insufficient room for puller hooks.

- The separating jaws are clamped by tightening the nuts on the side bolts evenly.

- Protects sensitive components thanks to the smooth, even surface of the large contact areas.

Produktvideo

Produkt-Varianten

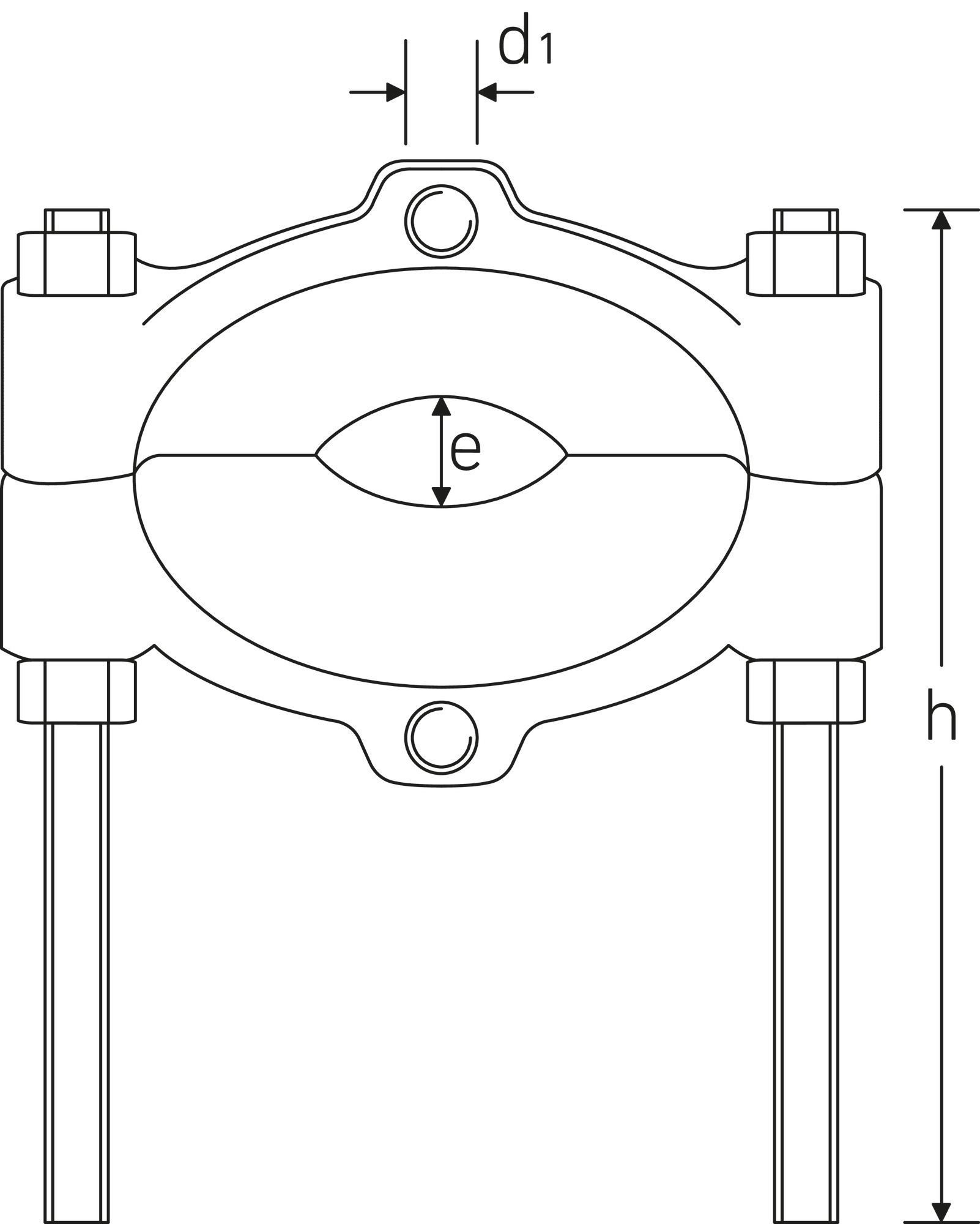

| Product no. | Size | Model | Model No. | for thread | Height mm (h) | Spreading range (e) min./max. | Weight (g) | |

|---|---|---|---|---|---|---|---|---|

| 71050016 | 1 | 11500 | 11500/1 | M10 | 0 mm | 5-60 mm | 500 g | Jetzt entdecken |

| 71050017 | 2 | 11500 | 11500/2 | M10 | 0 mm | 12-74 mm | 900 g | Jetzt entdecken |

| 71050018 | 3 | 11500 | 11500/3 | M14 x 1,5 | 0 mm | 22-115 mm | 2400 g | |

| 71050019 | 4 | 11500 | 11500/4 | M18 x 1,5 | 0 mm | 30-155 mm | 4700 g | Jetzt entdecken |

Eigenschaften

- for pullers 11501/1-4

- for separating and removing ball bearings, roller bearings, bushings, wheels and other tightly fitting parts

- the puller pins of the puller are screwed into the separation assembly

- seperator jaws slide under the component to be removed

- zinc plated

Produkt-Highlights

Gentle separation and removal.

The wedge-shaped contact surfaces have an even surface that protects sensitive components during the separation or puller process.

Safe removal in confined spaces.

The sharp, precisely executed cutting edges enable reliable removal of tightly fitting parts, even where there is insufficient space for conventional extractor hooks. For example, ball bearings, gear wheels or pulleys can be securely gripped and pulled off in a controlled manner - ideal for tight installation situations in workshops, maintenance and industry.

Controlled clamping of the cutting jaws.

The cutting jaws are tensioned symmetrically by tightening the nuts on the side bolts evenly on both sides. This ensures even force distribution, a secure hold and reduces the risk of jamming during removal - particularly helpful when precisely cutting and removing tightly fitting components such as bearings, bushings or wheels.

High quality.

STAHLWILLE is known for high-quality tools. The tool is carefully designed, made of robust steel and additionally zinc plated for high durability and resistance to high loads.