Inhalt

01.

The most important trigger mechanisms in clicking torque wrenches

In order to produce a bolted connection with an exactly defined preload force, the fastener must be tightened using torque, at least, and, if necessary using torque & torque angle. Controlled tightening is just as indispensable for private individuals as it is for international industrial enterprises in today's world. To enable controlled tightening, a suitable measuring device, such as a torque wrench, is required.

A basic distinction is made between clicking and indicating torque wrenches. Their functionality is provided by a mechanical, electronic or electromechanical method, which is a hybrid of the first two types.

Mechanically triggering torque wrenches use the following mechanisms:

02.

System A – the slipper wrench

In the slipper wrench, a bolt connected to a spring engages positively in a mating cam recess. Depending on the torque set, the spring is strongly or less strongly tensioned and thus presses the bolt more or less powerfully into its detent position in the cam recess. When the defined tightening torque is reached, the bolt slips out of the recess with a noticeable jerk. Depending on the version, this trigger mechanism can have up to six recesses. STAHLWILLE now only uses this method in a modified form for torque screwdrivers up to 10 N·m.

Advantages:

- It is not possible to overtighten or overtorque the fastener, making this method ideally suited for low torques.

Drawbacks:

- At high torques, it is difficult to control the force actually applied at the moment the tool trips. There is also a certain risk of injury.

- The spring has to be reset to »0« after use.

- This trigger mechanism is difficult to calibrate & adjust.

- Each recess has to be individually calibrated & adjusted.

03.

System B – knuckle joint

A spring-loaded linkage is used to trip the knuckle joint mechanism. In the rest position, it is angled. When it trips, it moves towards the center and contacts a bolt. Depending on the set torque, the spring tension will be either lower or higher, so that a force specific to this torque is required to change the position of the knuckle joint.

Advantages:

- This triggering method offers strong tactile feedback when tripped.

Drawbacks:

- Compared with other systems, this one is relatively susceptible to wear: it has a large number of friction points which are exposed to high loads depending on the torque value.

- The spring has to be reset to »0« after use.

- This torque wrench is difficult to calibrate & adjust.

04.

System C - triggering cam

The triggering cam mechanism involves a spring-loaded bolt pressing against the underside of the triggering cam. At the same time, the upper side of the triggering cam is pressed against the upper switching element and blocks it. When the preset torque is reached, the triggering cam tilts down and releases the upper switching element.

Advantages:

- This system offers good tactile feedback.

- The amount of wear is comparatively low because there are fewer friction points.

- Measurement is more precise than a slipper wrench or knuckle joint wrench.

Drawbacks:

- The spring has to be reset to »0« after use.

- This torque wrench is difficult to calibrate & adjust.

05.

System D – tilt blocks

With this release system, the force of the spring acts on the "tilt block" between the trigger elements. The tension of the spring varies according to the pre-set torque. As soon as the target torque is reached, the block moves from its rest position to a tilted position and generates a click as well as a tactile signal.

Advantages:

- Triggering by means of a tilting block allows the tool to be switched easily between clockwise and anticlockwise tightening.

- This system is less susceptible to wear.

Drawbacks:

- The tools are comparatively expensive in production and to purchase.

- Tripping in the low torque range can hardly be heard or felt.

- The spring has to be reset to »0« after use.

- This torque wrench is difficult to calibrate & adjust.

06.

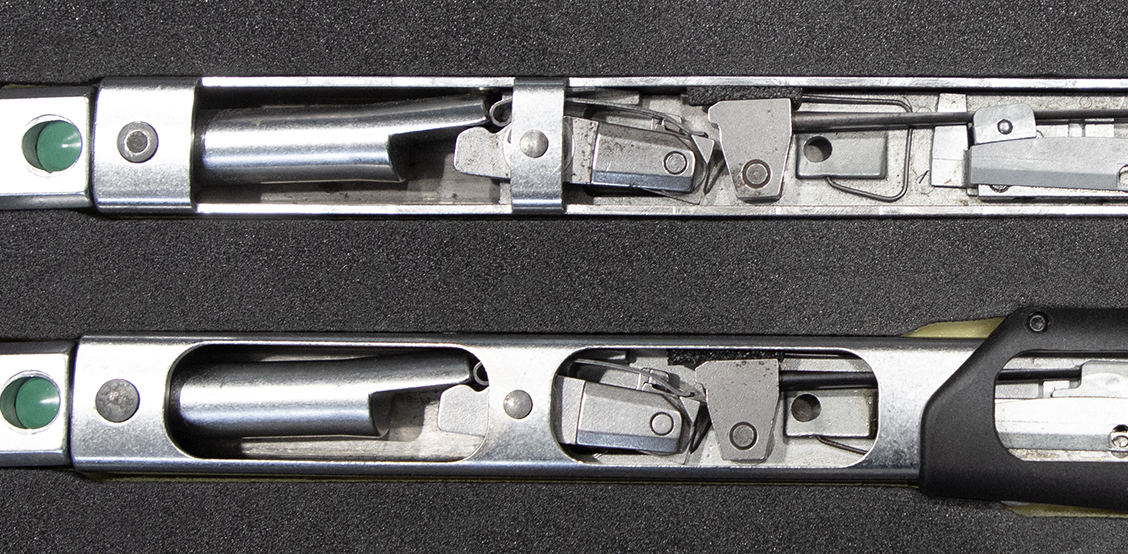

System E – triggering cam with a flexible rod

The triggering cam with a flexible rod is to be found in all STAHLWILLE mechanical torque wrenches. Moving the setting slide along the flexible rod changes the effective length of the lever arm. If force is applied to the torque wrench, the left-hand switching element tilts downwards and applies force to the right-hand element, forcing it up where it is inhibited by the cam. As soon as the resistance of the flexible rod is overcome, the right-hand switching element continues its travel upwards which produces an audible and tactile signal.

Advantages:

- Tripping by means of the triggering cam and flexible rod is almost wear-free.

- Quick adjustment by the user, no disassembly of the torque wrench required.

- Where the working load is zero, the trigger mechanism is not preloaded. It is not necessary to reset to »0« to release tension.

- The tripping action produces clear tactile and audible feedback.

Drawbacks:

- The almost wear-free system has a complex construction. It relies on high-grade materials. This is why the production and acquisition costs are higher than for less durable constructions.

Service

2025© All Rights Reserved