18.10.2022

¿Qué debe saber sobre la extensión y el punto de aplicación de fuerza?

Inhalt

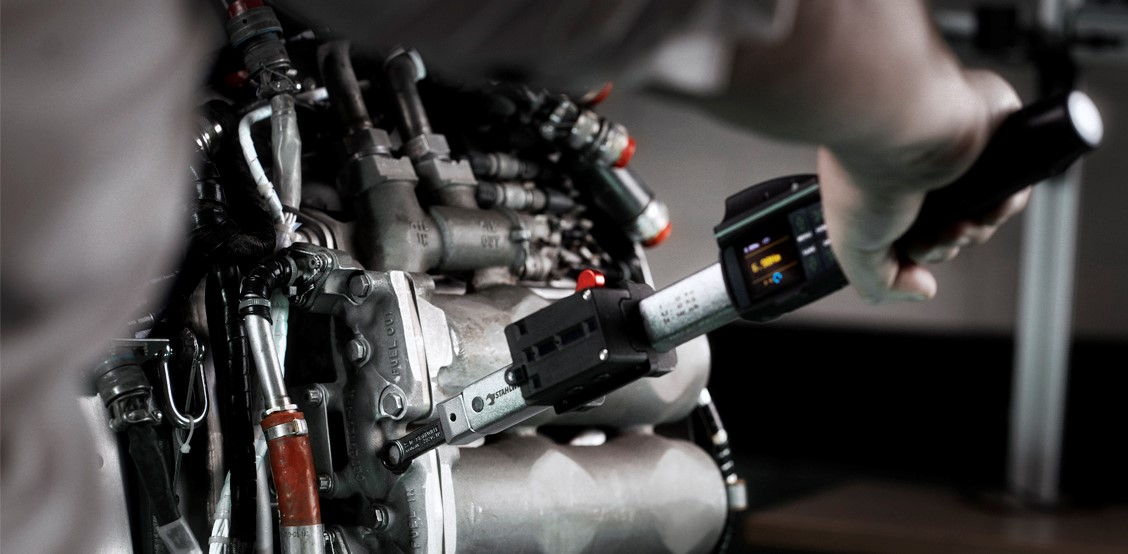

Se recomienda el uso de una llave dinamométrica siempre que una junta requiera un par de apriete específico. Si la llave dinamométrica está ajustada correctamente, se dispara cuando se alcanza ese par de apriete y muestra el valor de par de apriete correcto. Este es un requisito básico importante para alcanzar el par de apriete nominal correcto. Pero eso por sí solo a veces no es suficiente: otro aspecto crucial es el cumplimiento de la extensión, que puede variar de una llave dinamométrica a otra. Por eso es necesario tratar los temas del punto de aplicación de la fuerza y la extensión. Incluso si se utiliza la extensión incorrecta, la llave dinamométrica activará o mostrará un valor, pero tenga en cuenta que los valores objetivo no serán correctos.

01.

Fuente de error: punto de aplicación de fuerza

El par de apriete corresponde a la fuerza aplicada multiplicada por la longitud del brazo de palanca. El punto de aplicación de fuerza define el punto en el brazo de palanca en el que la mano del usuario aplica realmente fuerza a la herramienta. Esto es importante por los siguientes motivos:

- Si el usuario no sujeta el mango de la llave dinamométrica en el punto medio del mango, el punto de aplicación de fuerza se desplaza.

- Este desplazamiento puede cambiar la longitud efectiva del brazo de palanca.

- Un brazo de palanca unos centímetros más largo o más corto puede falsear los resultados de medición: la llave dinamométrica puede dispararse demasiado pronto o demasiado tarde.

- El tornillo no tendrá el par de apriete correcto y no cumplirá con las especificaciones.

La elección correcta de la llave dinamométrica puede minimizar significativamente este riesgo.

- Algunas llaves dinamométricas mecánicas, por ejemplo, tienen mangos especiales ergonómicos que colocan automáticamente la mano en la posición correcta.

- Además, hay disponibles llaves dinamométricas que pueden medir y aplicar el par de apriete independientemente del punto de aplicación de fuerza, para la máxima seguridad.

02.

Extensión divergente: corrección necesaria

Otra fuente común de errores son los útiles insertables. Si tienen una extensión (S) diferente a la extensión estándar (SF) para esa llave dinamométrica, esto también falseará el resultado de la medición. La indicación o el valor de ajuste (W) de la llave dinamométrica se tiene que corregir. En otras palabras, los usuarios deben volver a calcular el par de apriete que desean ajustar. Si se salta este importante paso, el tornillo se apretará con un par de apriete incorrecto.

El valor de indicación o ajuste corregido (WK) se calcula con las siguientes fórmulas:

¿Qué se entiende por «extensión»?

Categoría: Efectos mecánicos

Símbolo/abreviatura: S

Unidad: [mm]

Explicación: Una longitud definida que puede cambiar al utilizar útiles insertables para llaves dinamométricas y que influye en el par de apriete aplicado.

Importante:

- Si se combinan adaptadores con útiles insertables o herramientas especiales, se utiliza la suma de las extensiones individuales (Σ S) en lugar de la extensión S.

- Para las herramientas especiales desplazadas lateralmente no existe ninguna fórmula, el factor de corrección debe determinarse de forma empírica, p. ej. mediante una medición de referencia.

Puede encontrar más información y ejemplos de cálculo en nuestro catálogo de productos STAHLWILLE

Empresa

Servicios

2026© All Rights Reserved