Electromechanical torque wrenches Service/Series MANOSKOP®

Electromechanical torque wrenches Service/Series MANOSKOP®

730D

- With patented electromechanical release: precise electronic measurement combined with the familiar mechanical ‘click’.

- Visual evaluation of the bolted connection.

- Easy documentation of the measured values on a PC via the USB interface.

- Adjustment and logical menu navigation are carried out via a clearly arranged and intuitive 4-button keypad.

- Automatic correction of the tightening torque for varying centre distances for error-free working with different insert tools.

Produkt-Varianten

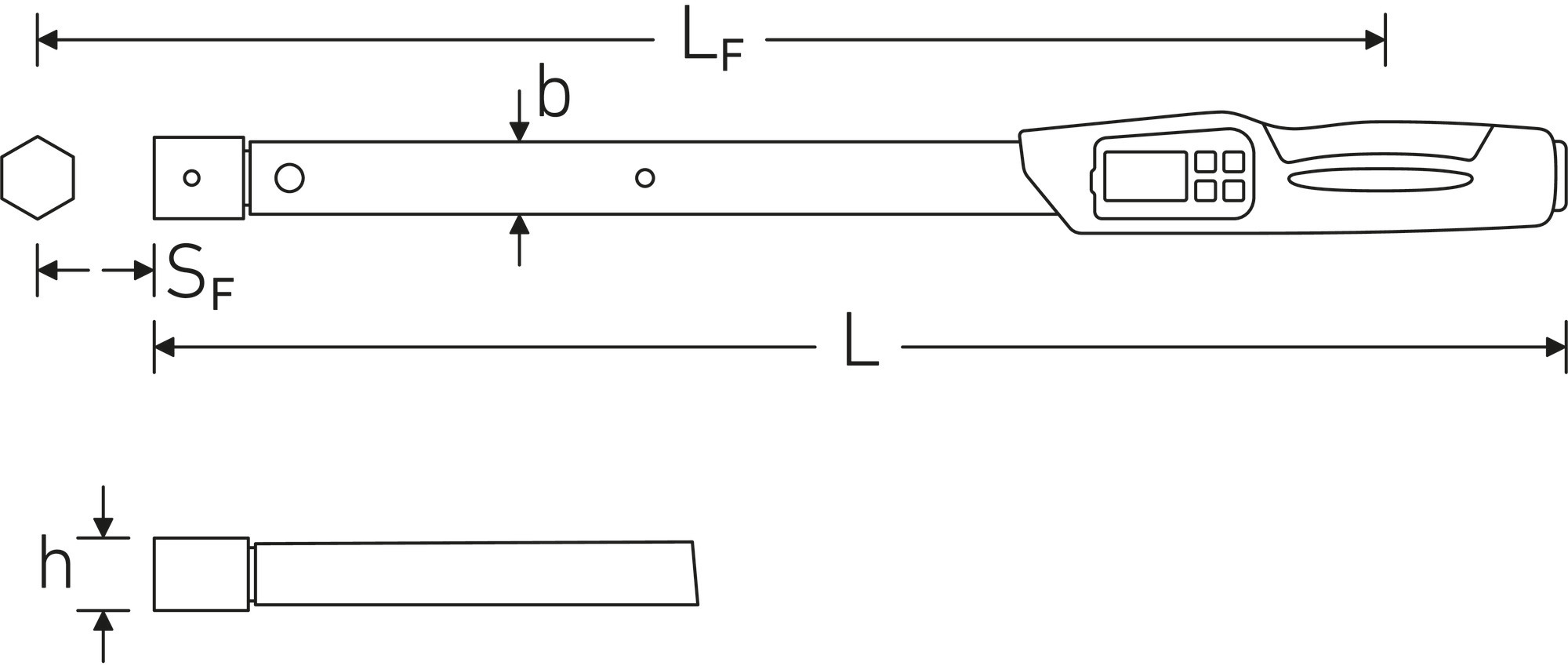

| Product no. | Size | Model | Measuring range N·m | Measuring range ft-lb | Measuring range in-lb | MA N·m | Nominal value N·m | Length mm (L) | Width mm (b) | Height mm (h) | Battery type | Adjustment display resolution ft-lb | Adjustment display resolution in-lb | Setting display resolution N·m | Tool holder size [internal square] | LF | SF | Weight (g) | Weight with box | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 96501710 | 10 | 730D | 10-100 N·m | 7,4-75 ft·lb | 90-900 in·lb | 10 N·m | 100 N·m | 467 mm | 28 mm | 23 mm | Mignon (AA) 1,5V | 0,2/0,1 ft·lb | 2/1,0 in·lb | 0,2/0,1 N·m | 9 x 12 mm | 426,5 mm | 17,5 mm | 1085 g | 1510 g | Jetzt entdecken |

| 96501720 | 20 | 730D | 20-200 N·m | 15-150 ft·lb | 180-1800 in·lb | 20 N·m | 200 N·m | 548 mm | 28 mm | 23 mm | Mignon (AA) 1,5V | 0,5/0,1 ft·lb | 5/1,0 in·lb | 0,5/0,1 N·m | 14 x 18 mm | 515 mm | 25 mm | 1361 g | 1896 g | Jetzt entdecken |

| 96501740 | 40 | 730D | 40-400 N·m | 30-300 ft·lb | 360-3600 in·lb | 40 N·m | 400 N·m | 688 mm | 28 mm | 23 mm | Mignon (AA) 1,5V | 1,0/0,1 ft·lb | 10/1,0 in·lb | 1,0/0,1 N·m | 14 x 18 mm | 655 mm | 25 mm | 3300 g | 5155 g | Jetzt entdecken |

| 96501765 | 65 | 730D | 65-650 N·m | 48-480 ft·lb | 580-5800 in·lb | 65 N·m | 650 N·m | 870 mm | 30,6 mm | 25,6 mm | Mignon (AA) 1,5V | 1,0/0,1 ft·lb | 10/1,0 in·lb | 1,0/0,1 N·m | 14 x 18 mm | 837 mm | 25 mm | 3300 g | 6000 g | |

| 96501965 | II/65 | 730D | 65-650 N·m | 48-480 ft·lb | 580-5800 in·lb | 65 N·m | 650 N·m | 892 mm | 30,6 mm | 25,6 mm | Mignon (AA) 1,5V | 1,0/0,1 ft·lb | 10/1,0 in·lb | 1,0/0,1 N·m | 22 x 28 mm | 889 mm | 55 mm | 3224 g | 7500 g | Jetzt entdecken |

| 96502080 | 80 | 730D | 80-800 N·m | 60-600 ft·lb | 720-7200 in·lb | 80 N·m | 800 N·m | 1160 mm | 30,6 mm | 25,6 mm | Mignon (AA) 1,5V | 1,0/1,0 ft·lb | 10/1,0 in·lb | 1,0/1,0 N·m | 22 x 28 mm | 1157 mm | 55 mm | 4577 g | 10500 g | Jetzt entdecken |

| 96502100 | 100 | 730D | 100-1000 N·m | 74-750 ft·lb | 900-9000 in·lb | 100 N·m | 1,000 N·m | 1344 mm | 30,6 mm | 25,6 mm | Mignon (AA) 1,5V | 1,0/1,0 ft·lb | 10/1,0 in·lb | 1,0/1,0 N·m | 22 x 28 mm | 1341 mm | 55 mm | 4995 g | 11000 g | Jetzt entdecken |

Technologien und Leistungsmerkmale

2-component handle

DIN EN ISO 6789-2

Eigenschaften

- patented electromechanical release

- acoustic and visual trigger signal

- mount for interchangeable insert tools

- QuickRelease safety lock

- quick setup via a convenient keypad

- extension length compensation function: automatic compensation of the tightening torque when a deviating extension length is entered

- overload protection by acoustic and optical warning signals

- automatic key lock prevents accidental adjustment of settings

- indicating mode functions in both directions

- units of measurement: N·m, ft·lb, in·lb

- different tolerance limits adjustable depending on the type of bolted joint

- optical evaluation of the results by green and red display

- additional locking of the presets (function mode, trigger or target value, unit of measure, tolerance value, saving, extension length) by PIN

- stores up to 7,500 results

- USB interface

- automatic warning of the next calibration date

- optimal calibration with perfectControl® calibration systems No. 7794 or calibration systems No. 7706, 7791

- in sturdy plastic box (sizes 40-100 in steel box)

- supplied with 2 x 1.5 V AA batteries. NiMH batteries AA/LR6, 1.2 V, can be used

- 2-component handle

- calibration certificate in accordance with DIN EN ISO 6789-2:2017

- accuracy ± 2%, ± 1 digit

Produkt-Highlights

Electromechanical cycle.

The MANOSKOP® with patented electromechanical cycle control measures the applied torque electronically. A visual evaluation of the bolted connection is provided by a display and signal lights on the side. Unlike a purely electronic torque wrench, the cycle and haptic user feedback are mechanical. A clearly perceptible cycle and an equally audible click indicate that the target value has been reached.

Comprehensive documentation.

Our electromechanical torque wrenches are documentation-compatible. They can be easily configured and programmed using the SensoMaster software. This allows all data to be read out, stored and further processed on a PC for better monitoring and optimisation of work processes. In addition, digital measurement enables precise cycling at the setpoint and documentation of the actual torque (actual value) applied during tightening.

Even for difficult areas of application.

STAHLWILLE electromechanical torque wrenches are ideal for areas of application where electronic torque wrenches reach the limits of their signalling capabilities - for example, when working overhead or when the display cannot be read. Even in loud, busy and very bright environments, where vibrations or optical and acoustic signals are difficult to perceive, electromechanical torque wrenches can indicate when the target value has been reached thanks to their patented haptic feedback.

Greater safety.

Our electromechanical torque wrenches minimise operating errors. For example, they can be used to parameterise and save bolted connections. The torque wrench then automatically sets the trigger torque for the selected bolted connection. The clicking torque is also specified digitally with precision, ruling out parallax effects (errors caused by an incorrect reading angle), which are possible when using a mechanical scale.

Intuitive operation with a clear display.

The LCD is easy to read and visually evaluates the bolted connection using coloured indicators. The keyboard, reduced to 4 keys, allows quick and error-free adjustment of all important parameters - from torque value, unit of measurement and tolerance limits to the storage of deviating reference dimensions.