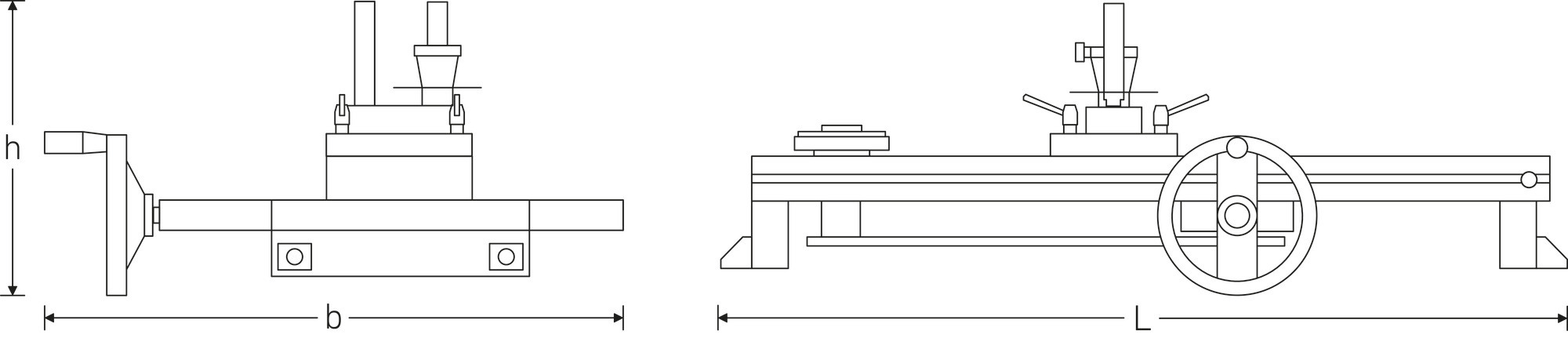

Manual calibration system

Manual calibration system

7791

Artikel-Nr. 52110091|EAN 4018754155439

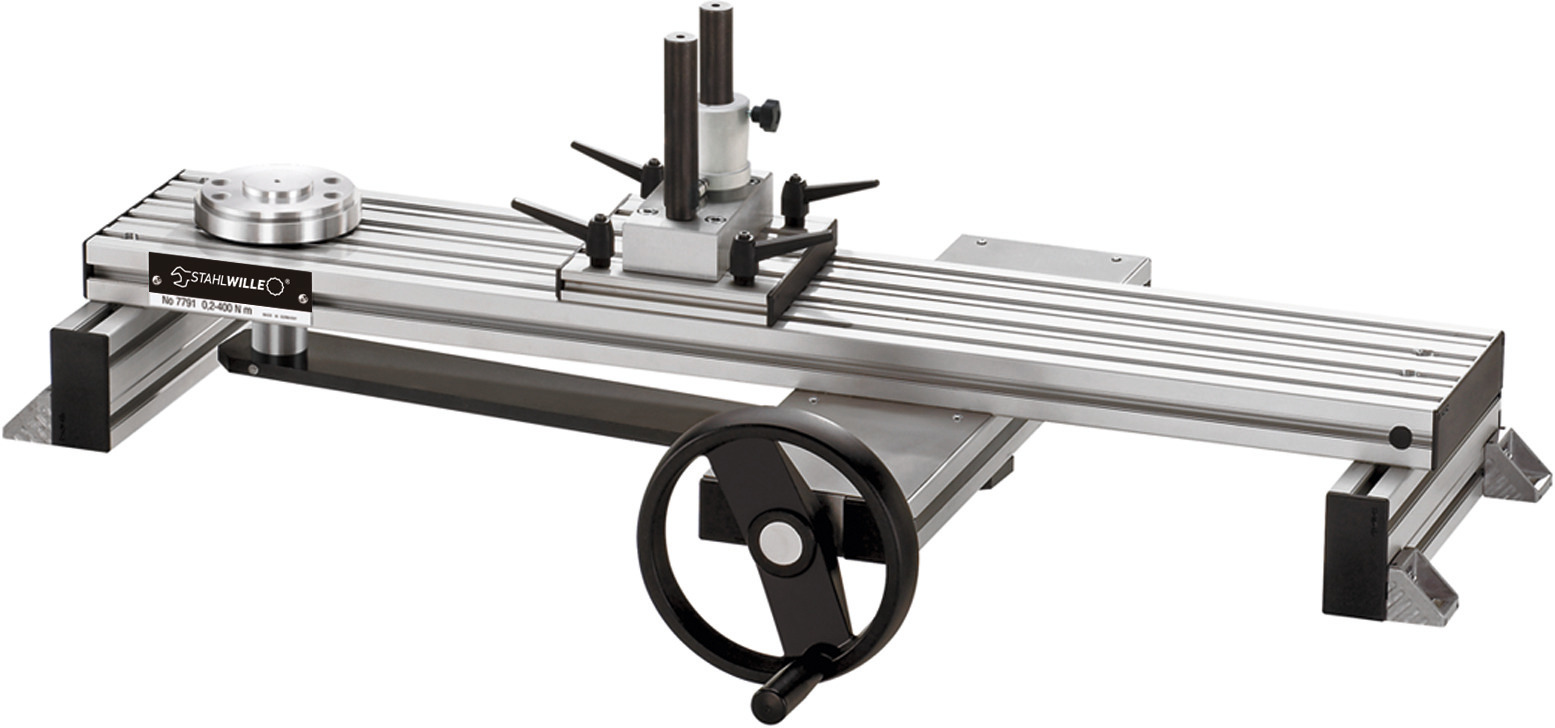

- Mechanical calibration system up to 400 N·m for torque wrenches and torque screwdrivers.

- MANUTORK® 7791 significantly reduces the effort and time required for calibration and adjustment of torque wrenches.

- A special force transmission system prevents the force application point from shifting during the calibration process.

- A handwheel drives a lever that is moved linearly by a spindle and thus transmits a rotational movement to the transducer.

- Reduced transverse forces on the pick-up and friction-free torque wrench support largely prevent accuracys.

Produkt-Varianten

| Product no. | Model | for transducers | Length mm (L) | Width mm (b) | Height mm (h) | Range N·m | Functional length (LF) max. mm | Profile width | Weight (g) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 52110091 | 7791 | size 1-100 | 1069 mm | 704 mm | 323 mm | up to 400 N·m | 815 mm | 180 mm | 44800 g |

Eigenschaften

- the special power transmission system prevents the force application point from shifting

- the handwheel drives a lever linearly via a spindle, whereby this movement is converted into a rotary movement of the transducer

- 2 ball-bearing bushings ensure a friction-free contact surface and enable the horizontal alignment of the wrench

- the torque wrench remains in position whilst the load is being applied

- minimal transverse forces and reduced friction minimise measurement errors

- protected by national and international patents

Produkt-Highlights

Even more possibilities.

Additional modules such as connecting to CAQ systems with an automated interface or advanced methods such as machine capability testing (MFU) are available by request.

In unserem Kundenportal bieten wir weitere Informationen und Downloads.

Company

Service

2026© All Rights Reserved