Motorised calibration and adjustment system

Motorised calibration and adjustment system

7794-2

- Motorised calibration and adjustment system for reducing time and effort.

- Intelligent and low-maintenance design that makes accuracys caused by incorrect operation almost impossible.

- In combination with the TorkMaster software, calibration certificates are issued in no time at all.

- Calibrations up to 1,000 N·m with easy-to-assemble extension No. 7791-1.

- USB interface for data exchange with the PC.

Produktvideo

Produkt-Varianten

| Product no. | Model | for transducers | Length mm (L) | Width mm (b) | Height mm (h) | Range N·m | Functional length (LF) max. mm | Profile width | Number of tools | Weight (g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 96521093 | 7794-2 | 7728 (size 1-100) | 1060 mm | 640 mm | 328 mm | 1-400 N·m | 815 mm | 180 mm | 19 pcs. | 51500 g |

Technologien und Leistungsmerkmale

QuickRelease

Eigenschaften

- measures without shifting the point of application of force

- avoid inaccurate measurements with the precise bearing spindle and the fine-controlled motor

- extremely precise calibration thanks to optimisation of the bearings and the square drives of the transducers

- clicking and indicating torque wrenches can be calibrated

- quick and easy switching of transducers with QuickRelease locking system

- convenient button operation for clockwise and counter-clockwise measurements with motorised loading and automatic speed adjustment

- bridge support with an eccentric clamp designed for single-handed operation reduces time and effort

- automatic transfer of measured values via USB interface to PC for further processing and archiving

- a declaration of conformity or calibration certificate can be printed or saved as a PDF file after calibration

- ‘as found’ and ‘as left’ calibrations can be documented

- DIN EN ISO 6789 calibration is supported in numerous languages. Additional standards and factory specifications available upon request

- upgradeable to the perfectControl® calibration system No. 7794-3 for angle controlled torque wrenches

- calibrations up to 1,000 N·m with easy-to-assemble extension No. 7791-1.

- calibration of transducers with torque reference wrench is possible on request

- recommended transducer laboratory No. 7728

- the interface adaptor set 7761/3 is required for automated calibration of electromechanical torque wrenches and screwdrivers (730D eClick, 714, 766 DAPTIQ®, TORSIOTRONIC®, TORSIOTRONIC® DAPTIQ®)

- registered design

- protected by national and international patents

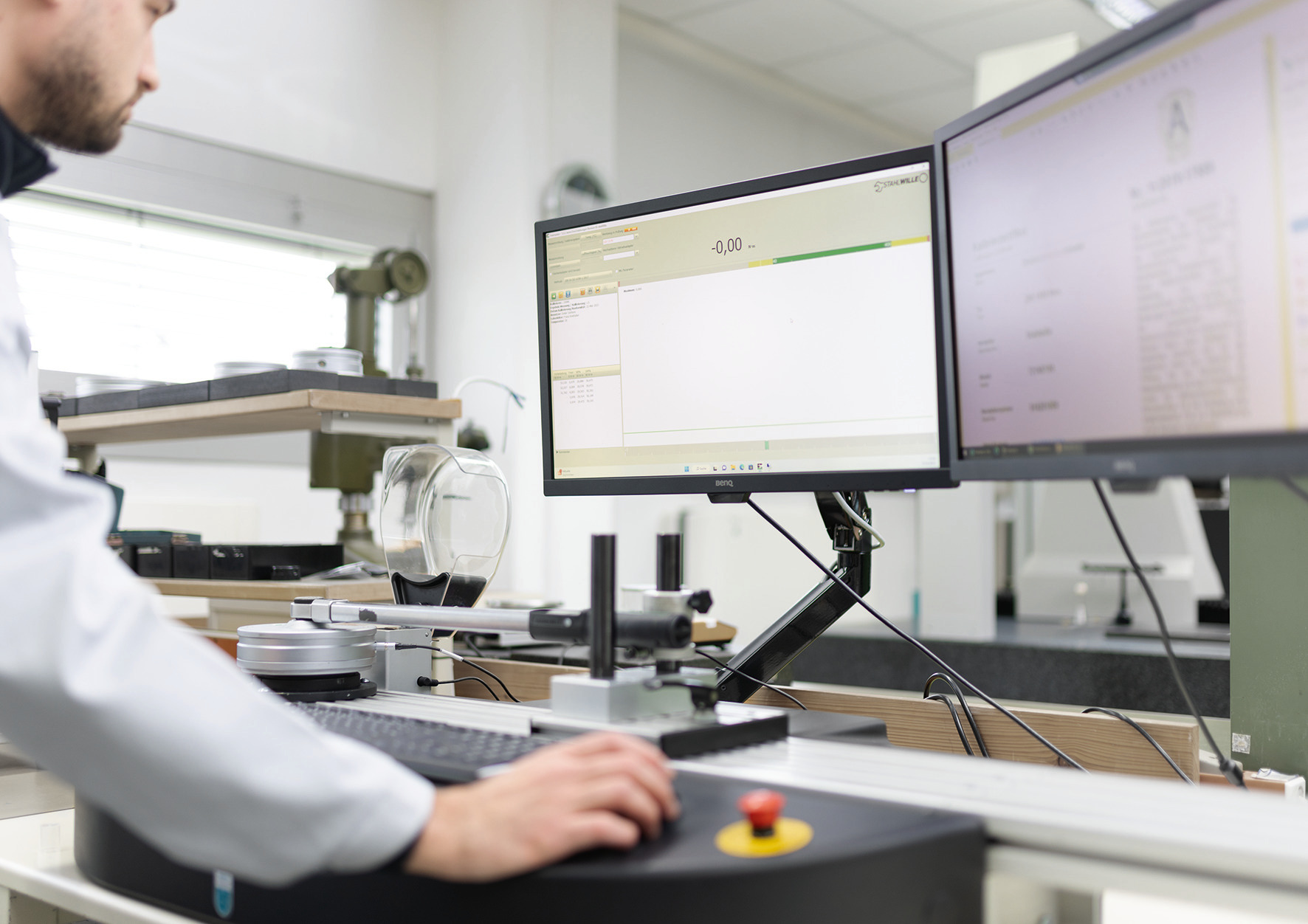

The electronic perfectControl® calibration system with motorised drive significantly reduces the time and effort required for calibrations and adjustments of torque wrenches

Contains 19-pieces:

1 motorised calibration and adjustment system No. 7794-2

Calibration accessory set:

6 calibration square drive insert tools No. 734K: Size 4, 5, 12, 20, 40, 100

6 square drive adaptors No. 409M, No. 7787, No. 7788, No. 7789, No. 7789-4, No. 7789-5

1 USB adaptor No. 7757-1

1 jack cable No. 7751

1 jack-push/pull cable No. 7752

1 jack-push/pull No. 7751-3

1 power adaptor set

1 hex L-Key No. 10760: 2 mm

Produkt-Highlights

Precision measurements.

perfectControl® calibration devices are the guarantee of controlled, reproducible force application, and provide accurate measurement results in conjunction with STAHLWILLE measurement devices and secure storage of the tool. All measurements take place without shifting the force application point.

Extremely efficient thanks to motorised operation.

The electrically powered perfectControl® 7794-2 reduces the amount of effort and time required to produce reproducible results.

Modular and versatile.

The perfectControl basic versions calibrate torque wrenches up to 400 N·m. Extending with module 7791-1 makes calibrations up to 1,000 N·m possible. The perfectControl basic versions calibrate torque wrenches up to 400 N·m. Extending with module 7791-1 makes calibrations up to 1,000 N·m possible

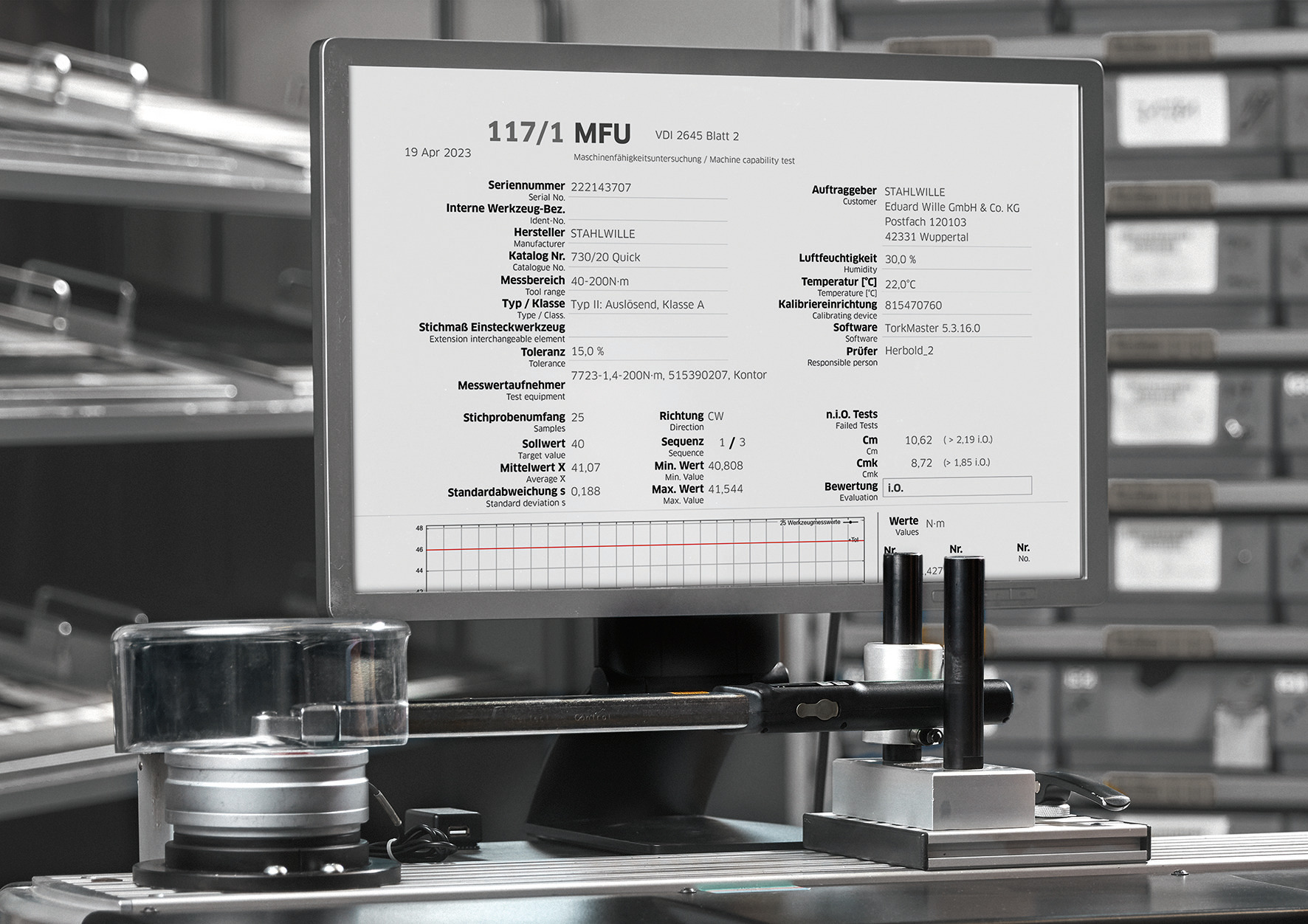

Calibration certificates in an instant.

The USB interface makes exchanging data with the PC seamless. In conjunction with the TorkMaster software, calibration certificates are issued in no time at all.

Even more possibilities.

Additional modules such as connecting to CAQ systems with an automated interface or advanced methods such as machine capability testing (MFU) are available by request.