18.10.2022

What you need to know about the extension and the point of application of force?

Inhalt

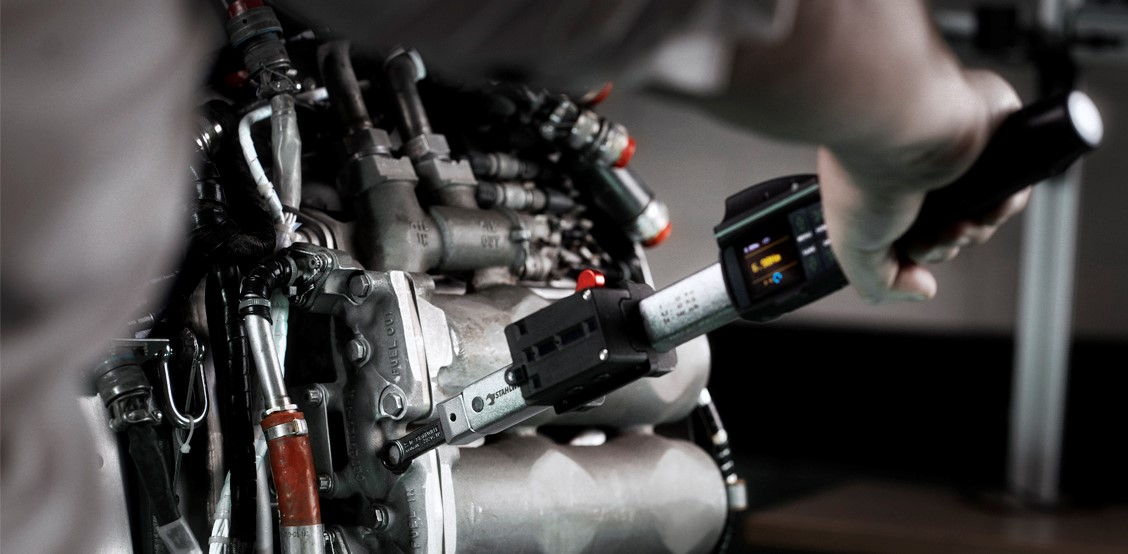

The use of a torque wrench is advisable wherever a joint requires tightening to a specified torque. If the torque wrench is correctly set, it trips when that torque is reached and displays the correct torque value. This is an important basic prerequisite to achieve the correct target torque. But that alone is sometimes not enough: another crucial aspect is adherence to the extension, which can vary from one torque wrench to the next. That is why it is necessary to deal with the topics of the point of force application and the extension. Even if the wrong extension is used, the torque wrench will trigger or display a value – but be aware that target values will not be correct!

01.

Source of error: point of application of force

The tightening torque corresponds to the applied force multiplied by the length of the lever arm. The point of application of force defines the point on the lever arm at which the user's hand actually applies force to the tool. This is important to know for these reasons:

- If the user does not grip the handle of the torque wrench at the mid-point of the handle, the point of application of force shifts.

- This displacement can change the effective length of the lever arm.

- A lever arm that is a few centimetres longer or shorter can falsify measurement results – the torque wrench may trip too early or too late.

- The fastener will then not have the right torque and will not comply with the specifications.

The right choice of torque wrench can significantly minimise this risk.

- Some mechanical torque wrenches, for example, have ergonomically shaped special handles that automatically locate the hand in the correct position.

- In addition, there are torque wrenches available that can even measure and apply the torque independently of the force application point – for maximum safety.

02.

Deviating extension: correction necessary

Another common source of errors are insert tools. If they have a different extension (S) from the standard extension (SF) for that torque wrench, this will also falsify the measurement result. The display or setting value (W) of the torque wrench will then have to be corrected. In other words: users have to recalculate the torque they want to set. If you skip this important step, the fastener will be tightened with the wrong torque!

The corrected display or setting value (WK) is calculated using these formulas:

What is meant by the "extension"?

Category: Mechanical influences

Symbol/abbreviation: S

Unit: [mm]

Definition: A defined length that can change when using insert tools for torque wrenches and which will have an influence on the torque applied.

Important:

- If adapters are combined with insert tools or special tools, the sum of the individual extensions (Σ S) is used instead of the extension S.

- There is no formula for laterally offset special tools – the correction factor in these cases will have to be determined empirically e.g. by means of a reference measurement.

You can find more information and sample calculations in our STAHLWILLE product catalogue

Company

Service

2026© All Rights Reserved