Service/Series MANOSKOP® torque wrenches

Service/Series MANOSKOP® torque wrenches

730a Fix

Artikel-Nr. 96583010|EAN 4018754269792

Produktvideo

Produkt-Varianten

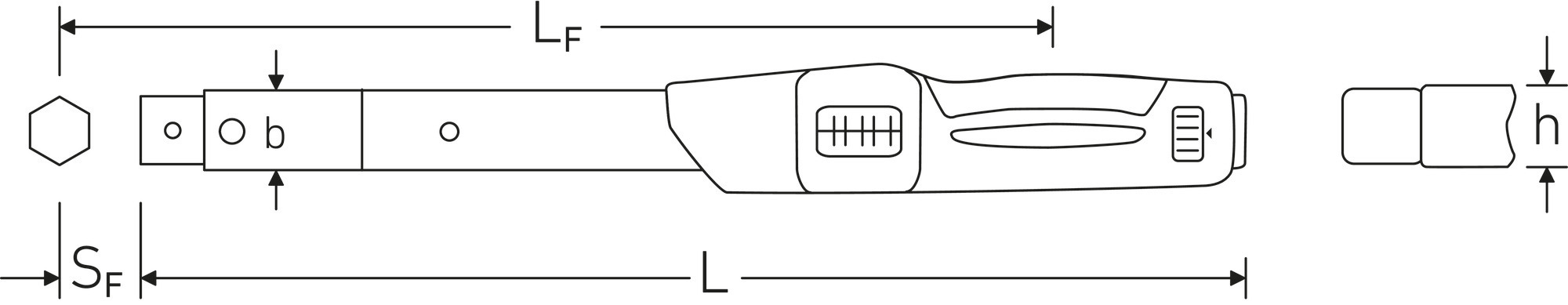

| Product no. | Size | Model | Measuring range ft-lb | Measuring range in-lb | Length mm (L) | Width mm (b) | Height mm (h) | Fine scale division | Tool holder size [internal square] | LF | SF | Weight (g) | Weight with box | Scale division in-lb | Scale division ft-lb | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 96583005 | a/5 | 730a Fix | 7-37 ft·lb | 90-450 in·lb | 330 mm | 28 mm | 23 mm | 2,5 in·lb | 9 x 12 mm | 280,5 mm | 17,5 mm | 832 g | 1638 g | 50 in·lb | 1 ft·lb | Jetzt entdecken |

| 96583010 | a/10 | 730a Fix | 15-75 ft·lb | 180-900 in·lb | 386 mm | 28 mm | 23 mm | 5 in·lb | 9 x 12 mm | 336 mm | 17,5 mm | 988 g | 1790 g | 100 in·lb | 2,5 ft·lb | |

| 96583020 | a/20 | 730a Fix | 30-150 ft·lb | 350-1800 in·lb | 467 mm | 28 mm | 23 mm | 10 in·lb | 14 x 18 mm | 424,5 mm | 25 mm | 1066 g | 2072 g | 100 in·lb | 5 ft·lb | Jetzt entdecken |

| 96583040 | a/40 | 730a Fix | 60-300 ft·lb | 800-3600 in·lb | 607 mm | 28 mm | 23 mm | 2 ft·lb | 14 x 18 mm | 564,5 mm | 25 mm | 1670 g | 2614 g | 100 in·lb | 20 ft·lb | Jetzt entdecken |

Technologien und Leistungsmerkmale

Value Lock (Tamper Resistant)

The target torque can be quickly adjusted using the adjustment knob. The knob can then be removed to prevent subsequent adjustment. The supplied locking screw and an adhesive seal provide additional protection against tampering.

Factory calibration certificate (ISO calibration)

Our torque tools, transducers, and test equipment are delivered with a factory calibration certificate in accordance with DIN EN ISO 6789-2:2017, and based on DKD-R 10-8 for traceability of the measuring equipment.

Low-wear flexible rod system

Our torque wrench is equipped with a low-wear trigger system with a bending beam. Unlike conventional torque wrenches with coiled springs, the flexible rod is not preloaded in unloaded state, which means that the 'spring' does not need to be reset to '0' after use.

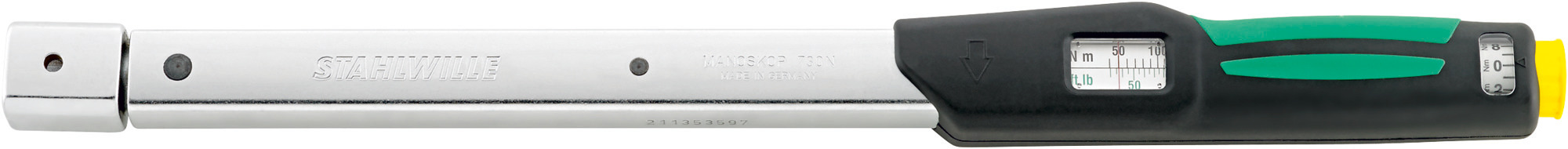

2-component handle

Our 2-component handle is non-slip and ergonomically designed. It is resistant to the most common oils, greases, fuels, brake fluids, and Skydrol. The arrow markings on the handle indicate the direction of operation.

Eigenschaften

- for work in series production

- clicking type with dual stop signal

- adjustment knob can be unscrewed after setting the desired torque value- subsequent changing of the setting is thus prevented

- the included TORX® Tamper Resistant locking screw also protects against tampering, as well as the included self-adhesive seals. no adjustment is possible without breaking the seal

- no reset to '0' required

- the measuring element is only under load when a force is applied

- fast, precise adjustment with QuickSelect quick adjustment

- dual scale ft·lb/in·lb

- mount for interchangeable insert tools

- with QuickRelease safety lock

- clicking mechanism insensitive to continuous loads and counter-loads (up to the max. measurement range of the torque wrench)

- counter-clockwise tightening by flipping the insert tools over

- optimal calibration with perfectControl® calibration systems No. 7794 or calibration systems No. 7706, 7791

- easy adjustment without disassembly via 2 external adjustment screws

- with 2-component handle

- calibration certificate in accordance with DIN EN ISO 6789-2:2017

- accuracy ± 3%

Produkt-Highlights

Adjustment does not require disassembly.

Quick adjustment from outside, no disassembly of the torque wrench required, with 2 adjustment points for the maximum & minimum values.

Clear fine adjustment.

The easy-to-use and easy-to-read double scale in N·m/ft·lb allows precise and easy target torque adjustment for reliable and accurate application.

In unserem Kundenportal bieten wir weitere Informationen und Downloads.